Hydraulic Mulch: Important Differences Between Cellulose and Wood Fiber Mulches and Advanced Fiber Matrices

Independent large-scale testing verifies that specifications for hydroseeding mulch should be written very clearly to distinguish between mulch made from paper and mulch made from wood chips. This distinction is based upon the respective performance capabilities of the two different types of mulch.

CELLULOSE MULCH

Once paper or cellulose mulch is applied, it forms a two-dimensional matrix, meaning it does not exhibit any significant vertical dimension, or loft. Paper lies flat on the ground, and it is not as effective as wood fiber mulch at holding moisture or preventing erosion. Once paper dries, it forms a “paper maché,” which is difficult for young seedlings to grow through. Independent testing and years of experience in the field has taught us that use of cellulose mulch should be limited to the tacking blown straw or the seeding of flat to gently-sloped areas (less than 4H:1V) where an irrigation system is in place to keep the paper moist.

WOOD MULCH

Wood fiber mulch, on the other hand, is derived from wood chips that are ground between large steel plates until the chips are converted to fine intertwined fibers. Profile® uses the thermal refining process which maximizes mulch performance.

ATMOSPHERIC VS. THERMALLY REFINED® WOOD FIBERS

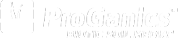

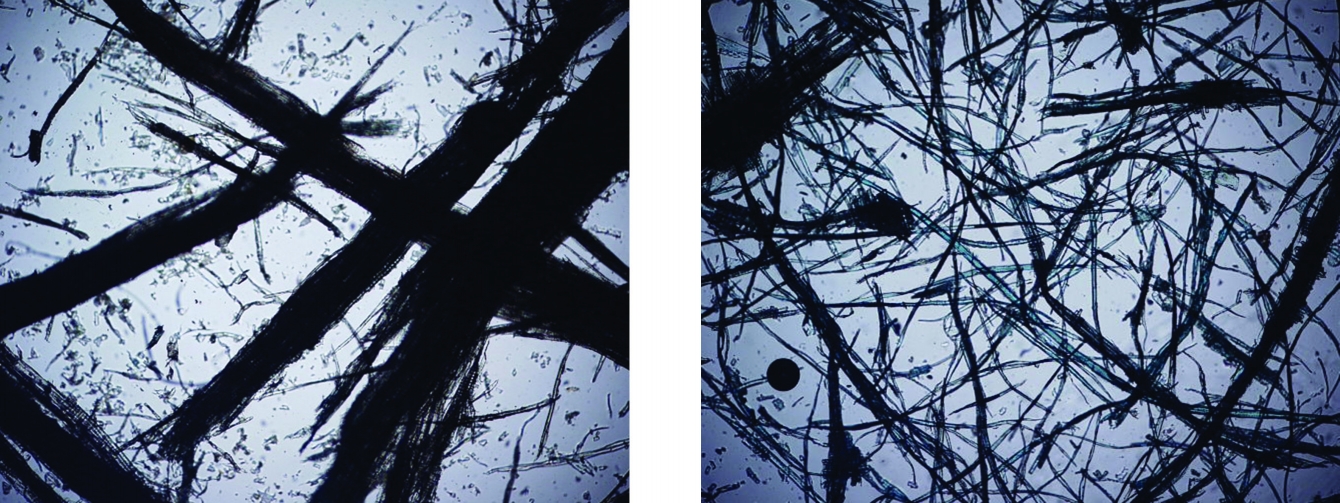

Many wood fiber mulches are manufactured using an atmospherically refining process that creates short, coarse fibers with less loft and interlock. This significantly impacts yield, coverage and water-holding capacity. As seen in the images below, Thermally Refined wood fibers are very fine and have dramatically more surface area which generates greater yield, loft and coverage, and water-holding capacity compared to the coarse and short fibers produced from the atmospherically refining process.

Regardless of the processing, however, wood fibers hold more moisture than paper, which makes wood fiber mulch superior at establishing vegetation, especially where irrigation is not in place. In addition, the three-dimensional matrix of wood fiber mulch provides more protection against the impact of rainfall, and therefore is superior at preventing erosion.

KEY DIFFERENCES BETWEEN CELLULOSE AND WOOD MULCHES:

- Many states and provinces have prohibited use of paper mulch because it doesn’t hold as much moisture or prevent erosion as well as wood fiber mulch.

- Erosion potential is always present; typically broken into categories i.e. high or low.

- Paper mulch is only 45% effective at preventing erosion (per large-scale independent testing).

- Thermally Refined Wood fiber mulch with no performance enhancing additives is 70% effective at preventing erosion.

- Wood fiber mulches are superior to paper at promoting vegetation establishement (per ASTM standard testing methods).

- Profile does not recommend applying paper mulch products on slopes steeper than 4H:1V due to inadequate erosion control performance. Specifiers should only consider wood fiber mulch on slopes steeper than 4H:1V based superior erosion control performance (per ASTM standard testing methods).

- For steeper or longer slopes and where greater erosion protection is required (greater than 75% effective), advanced fiber matrices are available to replace cellulose and wood fiber mulches and ensure erosion prevention and vegetation establishment. These include Stabilized Mulch Matrix (SMM), Bonded Fiber Matrix (BFM), Engineered Fiber Matrix™ (EFM™), High Performance-Flexible Growth Medium™ (HP-FGM™) or Extended Term-Flexible Grown Medium™ (ET-FGM™).

RECOMMENDED MULCH CHARACTERISTICS AND THEIR USE

When comparing the four base paper and wood mulches listed below, the key items to note are the differences in the maximum slope inclinations, slope lengths and the erosion prevention capabilities.

| Cellulose (Paper) Mulch | Cellulose (Paper) Mulch with Tackifier | Wood Fiber Mulch | Wood Fiber Mulch with Tackifier | |

| Max Slope | ≤ 4H:1V | ≤ 4H:1V | ≤ 3H:1V | ≤ 3H:1V |

| Application Rate on Max Slope |

1,500 – 2,000 lb/ac (1,680 – 2,240 kg/ha)

|

1,500 – 2,000 lb/ac (1,680 – 2,240 kg/ha |

2,500 lb/ac (2,800 kg/ha) |

2,500 lb/ac (2,800 kg/ha) |

| Max Slope Length* |

15 ft |

15 ft

(4.6 m) |

20 ft |

30 ft

(9.1 m) |

| Functional Longevity |

≤ 3 months

|

≤ 3 months | ≤ 3 months | ≤ 3 months |

| Percent Effectiveness | 45% | 50% | 70% | 75% |

*Maximum slope length is based on a 4H:1V slope. For applications on steeper slopes, the maximum slope length may need to be reduced based on actual site conditions.

Advanced Fiber Matrices

Advanced Fiber Matrices are wood based but engineered with crimped, biodegradable interlocking fibers and/or substances with adhesive properties to increase matrix and bond strength. They may also contain components that enhance water-holding capacity of the matrix.

If greater than 75% erosion prevention effectiveness is desired or slope gradients exceed 3H:1V, Advance Fiber Matrices should be specified.

|

Flexterra® High |

|||||

| Max Slope | ≤ 2H:1V | ≤ 2H:1V | ≤ 2H:1V | ≤ 0.25H:1V | ≤ 0.25H:1V |

|

Application Rate on Max Slope |

3,500 lb/ac (3,920 kg/ha) | 3,500 lb/ac (3,920 kg/ha) | 3,500 lb/ac (3,920 kg/ha) | 4,500 lb/ac (5,040 kg/ha) | 4,500 lb/ac (5,040 kg/ha) |

| Max Slope Length** |

50 ft |

75 ft |

50 ft |

100 ft |

125 ft |

| Cure Time | 24 - 48 hours | 4 - 8 hours | 4 - 24 hours | 0 - 2 hours* | 0 - 2 hours* |

| Functional Longevity | ≤ 6 months | ≤ 12 months | ≤ 12 months | ≤ 18 months | ≤ 24 months |

| Percent Effectiveness | ≥ 90% | ≥ 95% | ≥ 95% | ≥ 99% | ≥ 99% |

* HP-FGM and ET-FGM have very short cure times, and they can be applied onto wet soils and during a light rainfall.

** Maximum slope length is based on a 3H:1V slope. For applications on steeper slopes, the maximum slope length may need to be reduced based on actual site conditions.